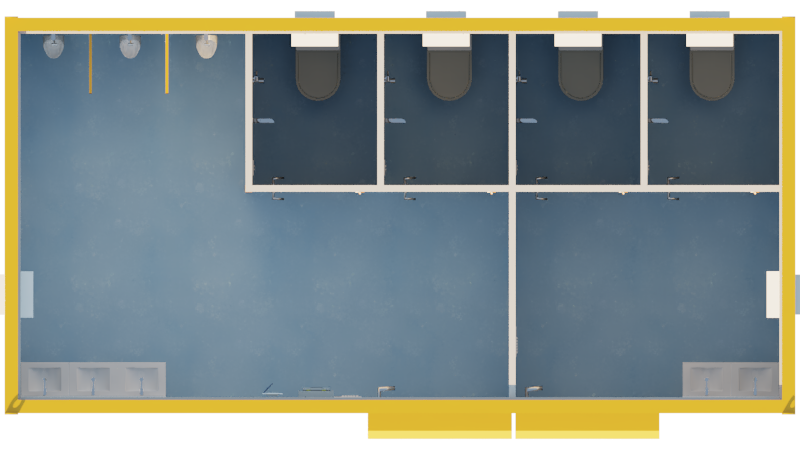

We are manufacturers and exporter of bunkhouse container toilets – 20ft x 8ft. Detail product description are as :

| S.No. | Bunkhouse Container Toilets Features |

Detail |

| 1 | Size (W x D x H) in Ft. | (20x 8 x 8.5)Ft. |

| 2 | Construction of materials | Steel: load bearing members : IS 10748 or equivalent

Side End walls : IS 1079 or IS 513 or Equivalent Roof : IS 1079 or IS 513 or Equivalent Plywood : Marine grade plywood, hardwood species Paint :Zn-rich Epoxy Primer (% volume of solid content 82-85%) |

| 3 | Welding | The shell of the structural cabin is of all weld construction. All the external welding will be continuous uniform and full of penetration. |

| 4 | Shell | The outer shell of the structural cabin will be manufactured with M. S. sheet equivalent to IS 1079 or IS 513 or Equivalent. The main load bearing member such as per posts, base, members, bottom side rail, top side rail & header are press formed profile of appropriate geometry. |

| 5 | Side and End Walls | External walls are vertically corrugated 1.2 mm thick ms steel sheet equivalent to IS 1079 or IS 513 or Equivalent. The Corrugated panel are continuously butt welded to form entire side wall and the assembled side wall is continuously welded to the peripheral frame members. The side and end walls will also provide cut outs for windows /doors. All the cut out after fixing the equivalent will be weather tight and proper channeling will be provided for the window opening. |

| 6 | Roof [self draining type] | The roof of the shell will be manufactured from 1.2 mm plain MS Sheet . |

| 7 | Surface Pretreatment | The dust and dirt are removed by blowing dry and clean oil free compressed air. |

| 8 | Painting | Primer Coat: Zinc Rich Epoxy Primer

Intermediate Coat : Epoxy Polyamide 60 microns. Top Coat : Chlorinated rubber paint 50 microns / bituminous paint. |

| 9 | Flooring Systems | 18 mm thick cement bonded sheet will be laid on top and secured by self tapping screws to the base members. |

| 10 | Insulation | Structural cabins will be insulated on sides ,end walls with 50 mm thick glass wool and the roof with 75 mm thick glass wool. |

| 11 | Inner Paneling | The interiors would be aesthetically finished so as to give a pleasing appearance with high quality workmanship. All joints as well as vertical and horizontal corners shall be neat and smoothly finished. The inside panel of sides, end walls & roof will consist of 4.0 mm thick Bakelite Sheet. Joints will be covered with anodized aluminum strip. False ceiling with approved ceiling sheet will be provided |

| 12 | Electrical | All wiring shall be concealed type inside the paneling and shall be of PVC insulated copper wire of ISI quality in PVC/Reinforced Steel Flexible Tubing/Conduits of ISI grade. |

| 13 | Plumbing and sanitary fittings | All the water line piping and connection are UPVC schedule-40. Drain line and connection are PVC schedule -40. All WC and Urinal are in ceramic material from cera/sanitation/equivalent make. |

| Detail Technical Specification of Bunkhouse Container Toilets |

||

| 14 | Bottom frame | 150 mm x 3 mm specially formed channel |

| 15 | Top frame | 150mm x 3 mm specially formed channel |

| 16 | Stiffeners Bottom | 100 mm x 50 mm square pipes |

| 17 | Stiffeners top | 100 mm x 50 mm square pipes |

| 18 | Side post | Specially formed 3.15 mm MS Post Sections |

| 19 | Side wall stiffeners | Specially formed 2mm MS Channels |

| 20 | Paneling Outside | 1.2 mm specially galvanized grooved sheet |

| 21 | False ceiling | 75 mm x 12 mm x 1.00 mm ms sections and white carbon board ceiling. |

| 22 | Bottom flooring | 18 mm cement bonded sheet with vinyl carpet |

| 23 | MS Door | Insulated door with door closer, locks, and handles |

| 24 | Insulation | 50 mm glass wool – 24 kg/m3 Density |

| 25 | Wiring | Concealed wiring -PVC conduits using fire resistance wires |

| 26 | Plumbing work | Water line : All the piping and connection work will be UPVC Schedule-40.

Drain Line : All the piping and connection work will be PVC Schedule-40. |

| 27 | Sanitaryware | 1] Western WC : 4 nos. 2] Toilet seat cover : 4 nos 3]Urinal : 2 nos. 4]Wash basin : 4 nos 5]Flush tank : 4 nos 6] Mirror cabin : 2 nos 7]Soap stand : 2 nos 8]Cloth hook : 2 nos 9]Two way bibcock : 4 nos 10]Health faucet : 4 nos 11]Pillar cock :4 nos 12]Angle cock :10 nos 13]Connection Pipe : 10 nos 14]Waste coupling : 4 nos 15]Drain sink coupling : 4 nos |

| 28 | Electrical fittings | Tubes, Door lights, Bulk Heads, Switches, sockets, telephones, ac points, Exhaust fans as per drawings. |

| 29 | Outside paintings | Phosphate the cabin internally & externally and painting with epoxy primer with two coat of epoxy textured paint. |