Pharma Grade High Purity Water system Installation at Erva Healthcare Pvt Ltd. in Rajkot, Gujarat, India.

Water Generation Capacity of the System: 250 LPH

Capacity of High Purity Water Storage Tank: 500 L

Raw Water Analysis:

- TDS: 1100 mg/l

- Electric Conductivity: 1.56 ms

- SDI Value: 2.1 mg/l

- Calcium: 125.3 mg/l

- Chloride: 545 mg/l

- Magnesium: 57.3 mg/l

- Total Alkalinity: 65 mg/l

- Silica: <5 mg/l

- Carbonate: 15 mg/l

- Bicarbonate: 48 mg/l

- Iron: 0.02 mg/l

- Fluoride: 0 mg/l

- Nitrite: 0 mg/l

- Zinc: 0.4 mg/l

- Aluminum: 0.2 mg/l

- Silver: 0.1 mg/l

- Copper: 0.2 mg/l

- Chemical Oxygen Demand: <5 mg/l

- Biology Oxygen Demand: <5 mg/l

Treatment Principle of Generation System:

Water Treatment Plant Based On State Of The Art Reverse Osmosis Technology & Ion Exchange Technology, Which Provides Treated Water At The Flow Rate Of 250LPH With Result Of Conductivity <1.3 MicroSim/Cm

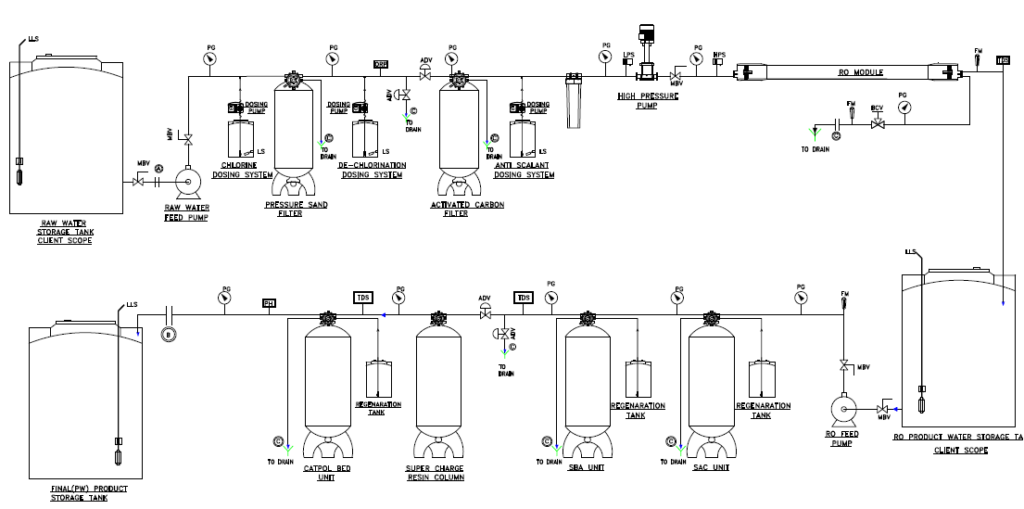

Treatment Scheme of Generation System:

- Pressure Sand Filter: Normally Raw water contains Suspended solids, which can be removed by deploying normal Filtration system. The filter consists of various layers of sand, Gravel, Pebbles etc. which are required to remove suspended solids up to 25 micron size from the raw water. Normally Bore well water contains suspended solids and other impurities. Considering these contents, different layers of Sand, Gravel, Pebbles and Cylex are used in media.

- Activated Carbon Filter: Normally Bore well water contains Organic contents, which is not permissible as per W.H.O. norms & may create Taste as well as odor problem. Apart from this, it may contain Color content, which has to be removed from the bore well water. Considering these contents, Activated carbon filter is provided, consisting of Activated carbon granule. This unit is a FRP vertical pressure vessel internally fitted with top distributor and bottom collecting system. This unit externally fitted with frontal pipe work and necessary valves.

- Anti Scalant Chemical Dosing System: The salt during desalination tends to deposit on membrane surface thus affecting the performance of RO system. To avoid deposition of salts on RO Membranes Anti-Scalent dosing is provided which reduces salt deposition on RO membranes and increases the cleaning cycle interval.

- Micron Cartridge Filter: High-suspended particles in water may choke the membrane passage and may also damage the membranes thus affecting performance and life of RO system. 5-micron cartridge filter removes the suspended particles from the feed water. Pressure Gauge across the filters is provided to identify the choking of filters and replacement of the same as per requirements. The micron cartridge filter has large surface area and may provide the breeding ground for microbial growth.

- Reverse Osmosis System: The pre-treated water then will be passed through Reverse Osmosis Module for Primary Salt Reduction from the water. Reverse Osmosis is the process, which removes the dissolved salt molecules through polyamide semi-permeable membrane by operating the system above the osmotic pressure, and reduces the salt content by 90 – 95%. Reverse Osmosis also removes suspended particles and reduces TOC etc. present in feed water.

- DM, Supercharge & Catpol System: The Permeate Water From Reverse Osmosis System Is Further To the DM System For Removal Of Dissolved Salt (Approx <150ppm) To Bring Down The Overall Conductivity <1 Micron Sim/Cm2. The DM System Is Designed With Strong Cation Bed & Strong Anion Bed Followed With Super Charge And Catpol. The System Removes The Entire Ionic Load From R.O. Water. The Treated Water After Catpol is Further Stored In Purified Water Storage Tank.

P&ID of Generation System: