Mechwat Technologies Private Limited are manufacturer of ACP Office Container in wide variety of range for various sector like construction site, mining project, power project, metro project, road project, oil field site, etc. Recently, Mechwat has supplied 20ft ACP Office container for Hindalco Industries Limited for Belgavi Mines, Belagavi, Karnataka.

Detail Description of 20ft ACP Office Container are as :

| S.No. | Features | Detail |

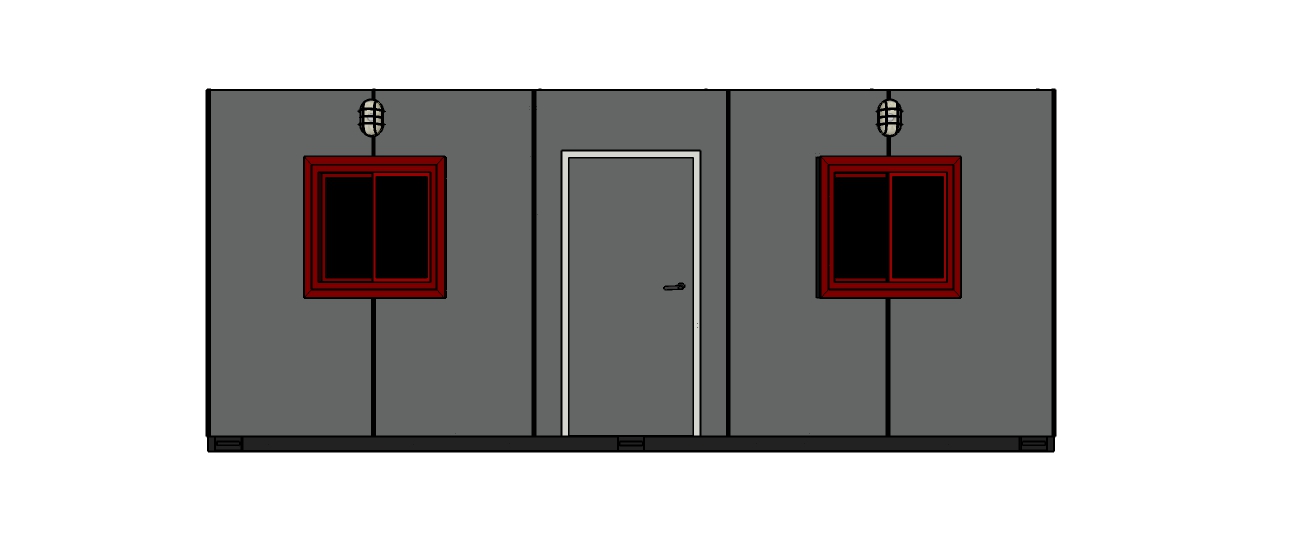

| 1 | Container Shell & Size | [LxWxH] : 20 ft x 10 ft x 8.5 ft. The shell fabricated from tested quality steel duly welded, comprising of base frame, peripheral structure, self-draining roof, entry door and windows. The four corner Column will be sufficiently strengthened to facilitate transportation, liftingand placing. |

| 2 | Base Frame | The base frame would be made of I Section having size of 100 mm x 50 mm. The main structural element will be 50 X 40 SQ pipe 3mm thick and cross membersshould be of square pipe having size of 50 mm x 30 mm x 3 mm |

| 3 | Side and End Walls | The side and end frame made out from square pipe having size of 50 mm x 50 mm x 3 mm and 50 mm x 25 mm x 3 mm. Exterior wall made up of 3 mm ACP sheet, whereas 8 mm thick decorative particle board wall cladding sheet to be used for interior walls. These ACP sheets will be treated for corrosion resistant by PVDF Coating. ACP Sheets will be Fixed by 3M Tape , Weather Proofing sealant and expansion bolt. All gaps to be sealed at edges and at seam, bottom etc. to prevent ingress of moisture. |

| 4 | Insulation | 50 mm thick Glass wool Insulation would be used for walls and 50 mm thick insulation material to be provided for roof and side walls. |

| 5 | Inner Panelling | The interior will be aesthetically finished so as to give custom built appearance with extremely high quality workmanship. All vertically and horizontal corners should be neatly and smoothly finished. The Panelling of side walls and roof will be of 8mm thick decorative partical board For Sanitation Unit or Ablution Block, Inner panelling will be done with 4mm thick 100% Water Proof Bakelite Sheets or 3mm thick ACP Panel. |

| 6 | Flooring Systems | On the bottom frame, 18 mm thick composite cement sheet will be fixed by means of self-tapping screw. 1mm thick type PVC Vinyl flooring will be fixed on the cement sheet. For Ablution/Sanitation Block, On the cement sheet, Anti Slippery Ceramic Tiles will be fitted with proper drainage arrangement. |

| 7 | Roof | Self-draining type roof will be made out of 3mm PVDF ACP Sheet, adequate roof bows are to be provided. Roof will be adequately cambered for draining of rainwater. Interior panelling would be done in 8 mm thick decorative laminated

plywood with adequate insulation |

| 8 | Windows | Aluminum windows 3’ feet x 3’ feet minimum, sliding type will be provided made of Aluminum Profile section, 10 mm thick toughen glasses. All windows/doors to have external weather shed. |

| 9 | Door | The size of the door will be of 6.5’ height x 3’.3” width. The door will be of external opening type made out of the same material as wall panels with door closing unit. The construction of the door would be double skin steel construction with 50 mm thick Glass wool insulation.The door interior will be finished with same material matching with that of the bunk house interior. The door will be provided with locking arrangement with separate handles on both sides of the

door as required- |

| 10 | Electrical System | The Bunk Houses will be provided with electrical wiring suitable for 250 volt, 50 HZ single phase AC power supply. All electrical wiring would be concealed. Bulk head and tube lights will be provided as required. Suitable copper cables will be used for lighting circuits. The cables used will be of 1.5 sq. mm. and 2.5 sq. mm. cables for lighting circuits. ISI mark and concealed in PVC conduits insulated copper wire will be used for wiring to be done in PVC conduit with small size distribution board with MCB protection and to separate with main supply. Light

fittings included LED lights, ceiling fans as per electrical plan will be provided. Internal switchboard and Pre-wiring for air conditioners will be provided. All plugs & sockets will be as per your Country’s Standard. Electrical Wiring and Fittings will be done as per your Country’s Standard- |

| 11 | Painting | All Steel components will be primed. Quoted with zinc chromate, primer. The external surfaces will be initially prime with Epoxy primer. And finally, Fine quality decorative Epoxy or PU paint will be applied in final stage- |

| 12 | Hooks & Legs | 8 Hooks on Top & Bottom of the cabin |

| 13 | Chair | 6 nos. Supreme 408 polyester office arm chair provided along with Site office cabin |

| 14 | Folding Table | 20 ft x 2.5 folding table made of 20 mm prelaminated plywood |

| 15 | White board | 1 m x 1m white board fixed by aluminum framing. |

| 16 | Electric Accessories | 6 Nos – DMT LED Tubelight [2 ft.]

2 Nos- 7w Mufasa Bulkhead 4 Nos – Computer Port |