Mechwat Are Manufacturer of Pharmaceutical Purified Water System in India.

We had Installed Pharmaceutical Purified Water System At- Sarthi Pharma, India.

Plant Type: Beta Lactam Manufacturing Facility (WHO- cGMP).

We are also providing customize water treatment plants for Pharmaceutical, Healthcare, Food-Beverages, Dairy, Chemical as well as Textile Industries.

(i.e. Raw water Pre-treatment plant, Soft water treatment Plant, RO Water Treatment Plant, Pre & Post Ultra-filtration plant, DM Plant as well as Electro-deionization plant).

We are also engaged with various industrial water applications. (i.e. Soft Water, Ultra filtered water, RO Water, DM Water, PW Water and also WFI Water Etc.).

TECHNICAL DETAILS OF SYSTEM:

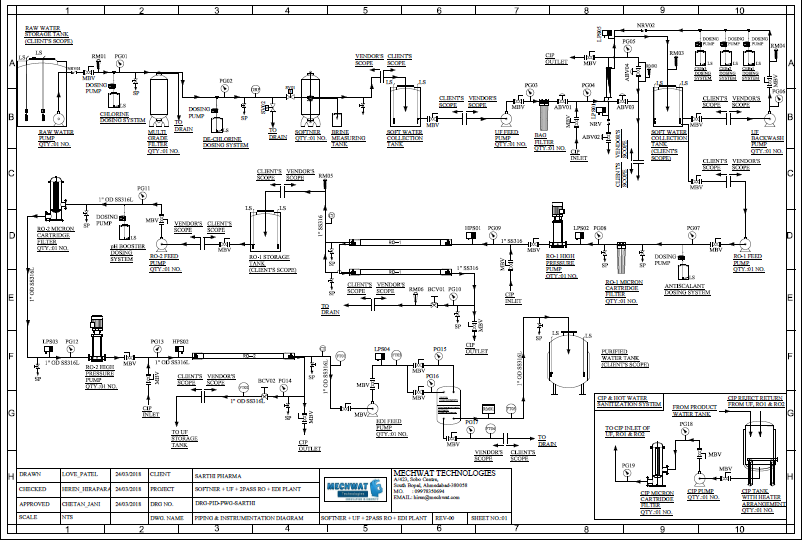

Title: RO-UF-EDI System

Category: Hot Water Sanitizable Purified Water system (Pharmaceutical Water System)

Design code: WHO- cGMP, USP

Type of Purified Water System: PLC Based Fully Automated with HMI Interface

Sanitation Method of System: Hot Water CIP System

Capacity: 250 LPH Generation & 4000 LPH Distribution Loop.

M.O.C. of Purified Water System: AISI 316 (MECHWAT manufacturing various type Purified Water Generation, Storage & Distribution System for example AISI 304, AISI 316 as well as FRP)

Surface Finish of Contact Parts Components Like Stainless Steel Tank, Tubes, Valves & Fittings: Internally Electro-polished and externally matt/mirror polished.

Considered Raw Water Analysis:

- pH: 7.4

- Total Dissolved solid: 1248 mg/l

- Total Hardness: 313.6 mg/l

- Turbidity: 2 NTU

- Silica: 8.5 mg/l

- Electric Conductivity: 1.83 ms/Cm2

- Iron: 0.4 mg/l

- SDI: 3.29

Designed Outlet Water Quality Parameter of System:

- Conductivity: 1.2 µs/cm

- pH: 5-7

- Total bacterial count: Less than 100 cfu/ml

- Total fungal count: Not more than 10 cfu/ml

- Color: Colorless

- Odor: Odorless

Water Purification Stage’s of Pharmaceutical Purified Water System:

- Multi Grade Filter & Activated Carbon Filter

- Softener

- Ultra-filtration stage

- Reverse Osmosis Stage-1

- Reverse Osmosis Stage-2

- EDI (Electro-Deionization)

- UV Stage

Chemical Dosing Systems of Pharmaceutical Water Generation System:

- Chlorination Dosing system

- De-Chlorination Dosing System

- CEB Dosing System

- Anti-scalant Dosing System as well as pH Dosing System

Water Storage & Distribution Stage’s of Purified Water System:

- Final Purified Water Storage

- Purified Water Pumping Stage

- UV Dosing Stage

- Point of Use Stage

- Return Loop Quality Checking Stage

- Return Storage / Spray in Tank Stage

User Point of Purified Water in Plant:

- Granulation-3 (GF-071)

- Blending-1 (GF-023)

- Dispensing Wash (G-019)

- Granulation-2 (G-015)

- Granulation-1 (G-018)

- Granulation-2 (G-015)

- Compression IPQC (G-029)

- Coating-2 (G-041)

- Solution Preparation (G-042)

- Service area (F-022)

- Coating-1 (G-044)

- Coating Wash (G-046)

- Compression Blending (G-049)

- Wash (G-054)

- Micro Lab (F-016)

- Instrumentation Lab (F-010) as well as in Chemical Lab (F-007)